Turbo Car Engine – An Important Part That Every Car Must Have

In the ever-evolving world of automotive engineering, turbo car engine have emerged as a cornerstone of modern vehicle design. These power units, equipped with turbochargers, compress air into the engine to increase its efficiency and power output. This technology has revolutionized the automotive industry by allowing smaller engines to produce the power of larger ones while maintaining better fuel economy. From high-performance sports cars to everyday sedans, turbocharged engines are now ubiquitous across various vehicle types. This article delves into the diverse range of turbocharged car engine models available in the market today, exploring their specifications, applications, and contributions to automotive innovation.

Understanding Turbocharged Engine Technology

Before diving into specific models, it’s crucial to understand how turbocharged engines work. A turbocharger is essentially an air compressor powered by exhaust gases. It forces more air into the combustion chamber, allowing for more fuel to be burned and thus generating more power. Modern turbocharged engines typically feature advanced technologies such as direct fuel injection, variable valve timing, and sophisticated engine management systems. These innovations help optimize performance while minimizing emissions and improving fuel efficiency.

Turbocharged engines come in various configurations, including inline (straight) engines, V-type engines, and flat (boxer) engines. Each configuration offers unique advantages in terms of packaging, weight distribution, and performance characteristics. Additionally, manufacturers often develop different versions of turbocharged engines within each family, offering varying levels of power output and features to suit different vehicle models and market segments.

BMW’s Turbocharged Engine Lineup

BMW has been at the forefront of turbocharged engine development, particularly through its TwinPower Turbo technology. The company’s modular engine strategy has resulted in several successful turbocharged engine families:

B48 Engine Family

The B48 is BMW’s 2.0-liter turbocharged four-cylinder engine, widely used across various models. It features:

- Power outputs ranging from 184 hp to 306 hp

- Aluminum construction for reduced weight

- Twin-scroll turbocharger for improved response

- High-pressure direct injection system

- Applications in 3 Series, X1, X2, and Z4 models

B58 Engine Family

As the six-cylinder counterpart to the B48, the B58 represents BMW’s premium turbocharged offering:

- 3.0-liter displacement with power outputs up to 510 hp in competition variants

- Closed-deck construction for enhanced durability

- Water-to-air intercooling system

- Used in M Performance models and high-end variants

S58 Engine Family

Developed specifically for high-performance applications:

- Successor to the legendary S55 engine

- Features in M3 and M4 Competition models

- Advanced cooling systems and strengthened components

- Capable of producing over 500 hp in standard trim

Mercedes-Benz Turbocharged Engine Portfolio

Mercedes-Benz has developed an extensive range of turbocharged engines under its M2XX designation:

M254 Engine Family

This latest generation of four-cylinder engines showcases cutting-edge technology:

- Mild hybrid integration with 48V electrical system

- Cylinder deactivation for improved efficiency

- Nanoslide cylinder coating technology

- Powers C-Class, E-Class, and GLC models

M176/M177 Engine Family

Representing Mercedes’ V8 turbocharged offerings:

- 4.0-liter twin-turbo configuration

- “Hot V” design with turbos positioned inside the V

- Outputs ranging from 469 hp to 630 hp

- Featured in AMG GT and high-performance SUVs

M139 Engine

One of the most powerful four-cylinder engines in production:

- Specifically developed for compact performance models

- Produces up to 421 hp in AMG applications

- Transverse mounting orientation

- Powers A45 S and CLA45 S models

Audi/Volkswagen Group Turbocharged Engines

The Volkswagen Group’s MQB and MLB platforms utilize several notable turbocharged engines:

EA888 Engine Family

Perhaps the most widespread turbocharged engine in the group:

- Available in 1.8L and 2.0L displacements

- Multiple generations with continuous improvements

- Used across Audi, VW, and SEAT models

- Power outputs from 150 hp to over 300 hp

VAG TSI/TFSI Range

These engines represent the core of Volkswagen’s turbocharged lineup:

- Includes 1.4 TSI, 1.5 TSI Evo, and various 2.0 TFSI variants

- Innovative technologies like ACT cylinder deactivation

- Widespread application in Golf, Passat, and Tiguan models

VR6 Turbocharged Variants

Unique to the Volkswagen Group:

- Compact VR6 design with turbocharging

- Used in performance-oriented models like Golf R

- Combines smoothness with high power density

Ford’s EcoBoost Engine Family

Ford’s EcoBoost technology has become synonymous with turbocharged efficiency:

2.3L EcoBoost

Versatile four-cylinder engine with wide application:

- Powers Mustang EcoBoost and Focus RS

- Produces up to 350 hp in performance variants

- Features twin-scroll turbocharger technology

3.5L EcoBoost V6

Flagship turbocharged engine for Ford trucks and SUVs:

- Standard in F-150 Raptor

- Generates up to 450 hp and 510 lb-ft torque

- Utilizes port and direct injection systems

1.0L EcoBoost

Demonstrates efficiency in small displacement:

- Award-winning three-cylinder design

- Available in Fiesta and Focus models

- Maintains strong performance despite small size

Japanese Manufacturers’ Turbocharged Offerings

Japanese automakers have developed distinctive turbocharged engines:

Toyota/Lexus Dynamic Force Engines

Modern turbocharged units with innovative features:

- 2.0L and 2.5L variants in various configurations

- High thermal efficiency designs

- Integrated with hybrid systems in some applications

Nissan VR30DDTT

Advanced V6 turbocharged engine:

- Successor to the renowned VQ series

- Powers Infiniti Q50/Q60 models

- Features twin turbochargers and direct injection

Subaru FA20F/FA24F

Horizontally opposed turbocharged engines:

- Used in WRX and BRZ models

- Optimized for all-wheel-drive applications

- Balances performance with daily usability

Specialized Turbocharged Engines

Certain manufacturers focus on niche turbocharged engine applications:

Porsche Turbo Engines

High-performance flat-six turbocharged units:

- Water-cooled designs with advanced cooling systems

- Powers 911 Turbo and GT models

- Incorporates variable turbine geometry

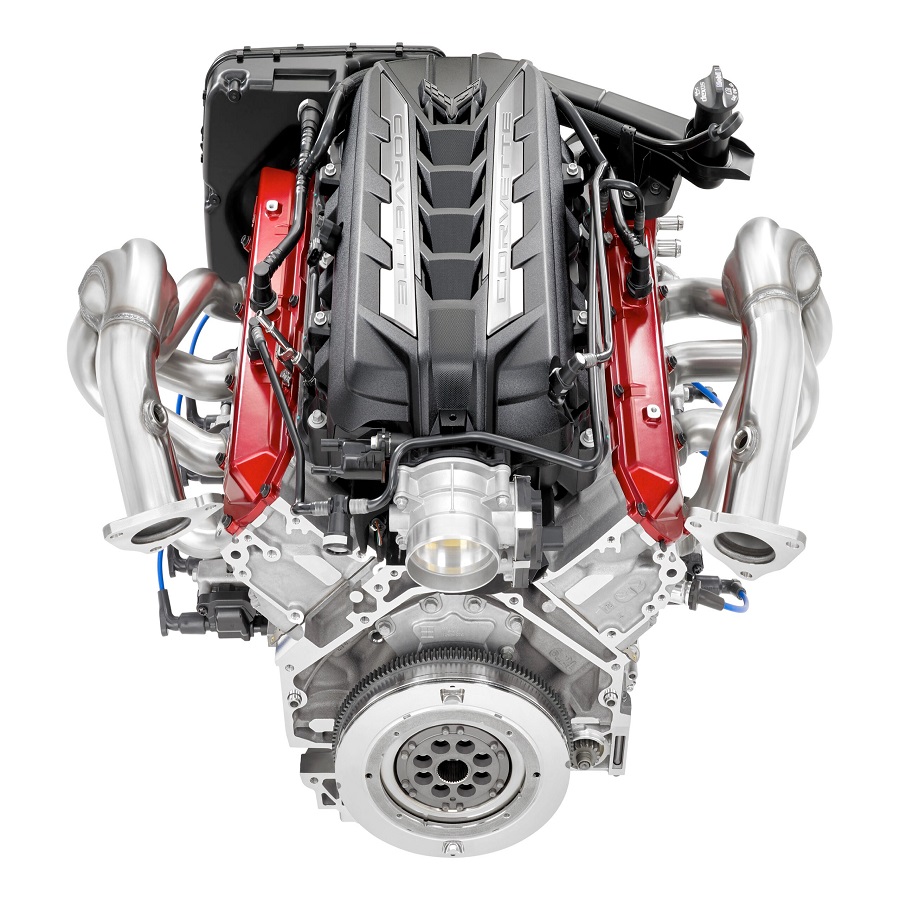

Ferrari Twin-Turbo V8

Revolutionary design in supercar segment:

- F154 engine family powers various models

- Features innovative “hot V” configuration

- Sets benchmarks for specific power output

Future Trends in Turbocharged Engine Development

The future of turbocharged engines looks promising with several emerging trends:

Electrification Integration

Combining turbocharging with hybrid systems:

- 48V mild hybrid assistance

- Electric turbochargers for instant response

- Improved efficiency through intelligent energy management

Variable Compression Technology

Innovations in engine flexibility:

- Infiniti’s VC-Turbo engine concept

- Adjustable compression ratios for optimal performance

- Balances power and efficiency dynamically

Advanced Materials and Manufacturing

New approaches to engine construction:

- Increased use of lightweight alloys

- Additive manufacturing techniques

- Enhanced thermal management systems

The role of turbo car engine

Turbocharged car engines have become a cornerstone of modern automotive technology, revolutionizing the way vehicles generate power and efficiency. These advanced power units utilize turbochargers to compress air entering the engine, allowing for greater combustion efficiency and significantly enhanced performance.

Basic Operating Principles

At its core, a turbocharged engine operates by utilizing exhaust gases to drive a turbine connected to a compressor. This system performs several critical functions:

- Air Compression: The turbocharger forces more air into the combustion chamber than naturally aspirated engines can achieve.

- Increased Oxygen Supply: Higher air density allows for more complete fuel combustion.

- Power Enhancement: The improved combustion process generates greater power output from smaller displacement engines.

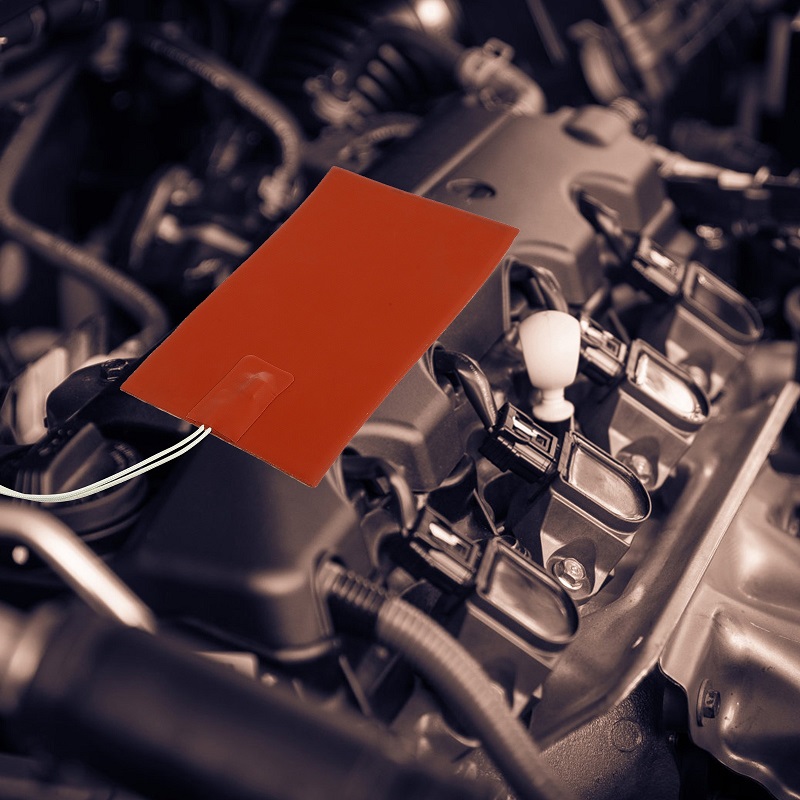

Key Components and Their Roles

The effectiveness of turbocharged engines depends on several specialized components:

- Turbocharger Housing: Protects and supports the turbine and compressor wheels.

- Wastegate: Regulates boost pressure to prevent over-pressurization.

- Intercooler: Cools compressed air to increase its density before entering the engine.

- Blow-off Valve: Releases excess pressure safely when throttle is closed.

Performance Advantages of Turbocharged Engines

Power Density Optimization

Turbocharging enables manufacturers to extract maximum performance from smaller engines:

- Downsizing Benefits: Four-cylinder turbo car engine can match or exceed the power of larger naturally aspirated six-cylinder units.

- Torque Characteristics: Turbo car engine typically produce higher torque at lower RPMs, improving drivability.

- Power Band Extension: Modern turbo systems maintain boost across wider RPM ranges.

Conclusion: The Enduring Impact of Turbocharged Engines

Turbocharged turbo car engine have fundamentally transformed the automotive landscape, offering unprecedented combinations of power, efficiency, and environmental responsibility. From BMW’s precision-engineered TwinPower Turbo units to Ford’s versatile EcoBoost family, each manufacturer brings unique expertise to turbocharged engine development. As we look toward the future, these engines will continue evolving alongside electrification trends, potentially leading to even more sophisticated hybrid turbocharged systems. The diversity of current turbocharged engine models demonstrates the technology’s adaptability across various vehicle segments and performance requirements.