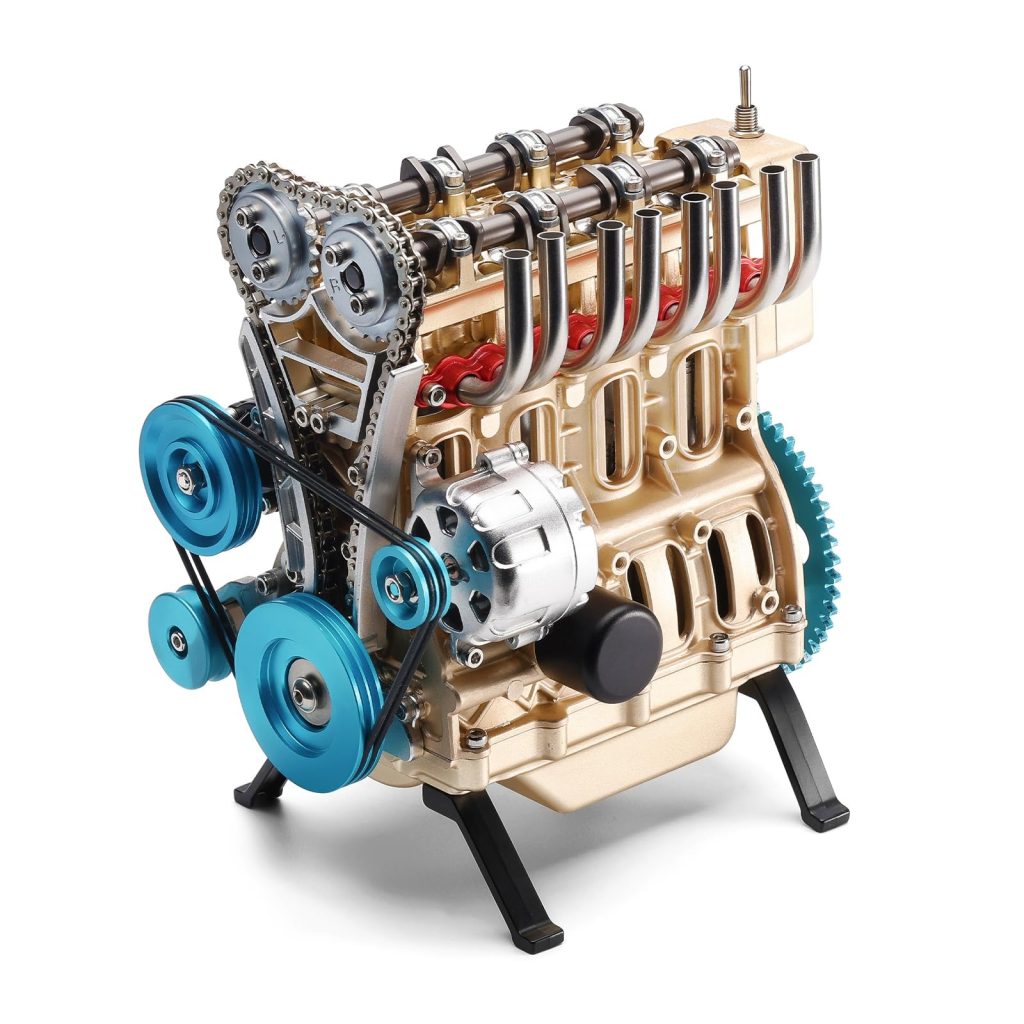

Car Engine Cylinder – Important Automobile Parts

The car engine cylinder is a critical component of a car’s internal combustion engine, where the fuel-air mixture is compressed and ignited to generate power. When it comes to installing a car engine cylinder, precision, attention to detail, and adherence to best practices are essential to ensure optimal performance and longevity. In this comprehensive guide, we will provide a step-by-step process for the proper installation of a car engine cylinder, covering the necessary tools, safety precautions, and best practices to help ensure a successful and efficient installation.

Pre-Installation Preparation

Before proceeding with the installation of a car engine cylinder, it is crucial to take certain preparatory steps to ensure a smooth and efficient process. This includes gathering the necessary tools and materials, preparing the work area, and adhering to essential safety measures.

Gather Necessary Tools and Materials

The first step in preparing for the installation of a car engine cylinder is to gather all the necessary tools and materials required for the job. This may include items such as a torque wrench, socket set, gasket sealant, engine oil, piston rings, cylinder head bolts, and other components specific to the make and model of the engine. Ensuring that all required tools and materials are readily available will help facilitate a seamless installation process.

Prepare the Work Area

Creating a clean, organized, and well-lit work area is essential for performing the installation of a car engine cylinder. Clear the workspace of any debris, tools, or clutter that may impede the installation process. It is also advisable to lay out the necessary tools and materials in a systematic and accessible manner to facilitate efficient access during the installation.

Adhere to Safety Precautions

Prior to commencing the installation process, it is imperative to observe all safety precautions to minimize the risk of injury and ensure a safe working environment. This includes wearing appropriate personal protective equipment such as safety goggles and gloves, as well as following any specific safety guidelines outlined in the vehicle’s service manual.

Installation Process

The actual installation of a car engine cylinder involves a series of sequential steps that require precision, attention to detail, and methodical execution. Each stage of the process is crucial in ensuring the proper installation and functioning of the engine cylinder.

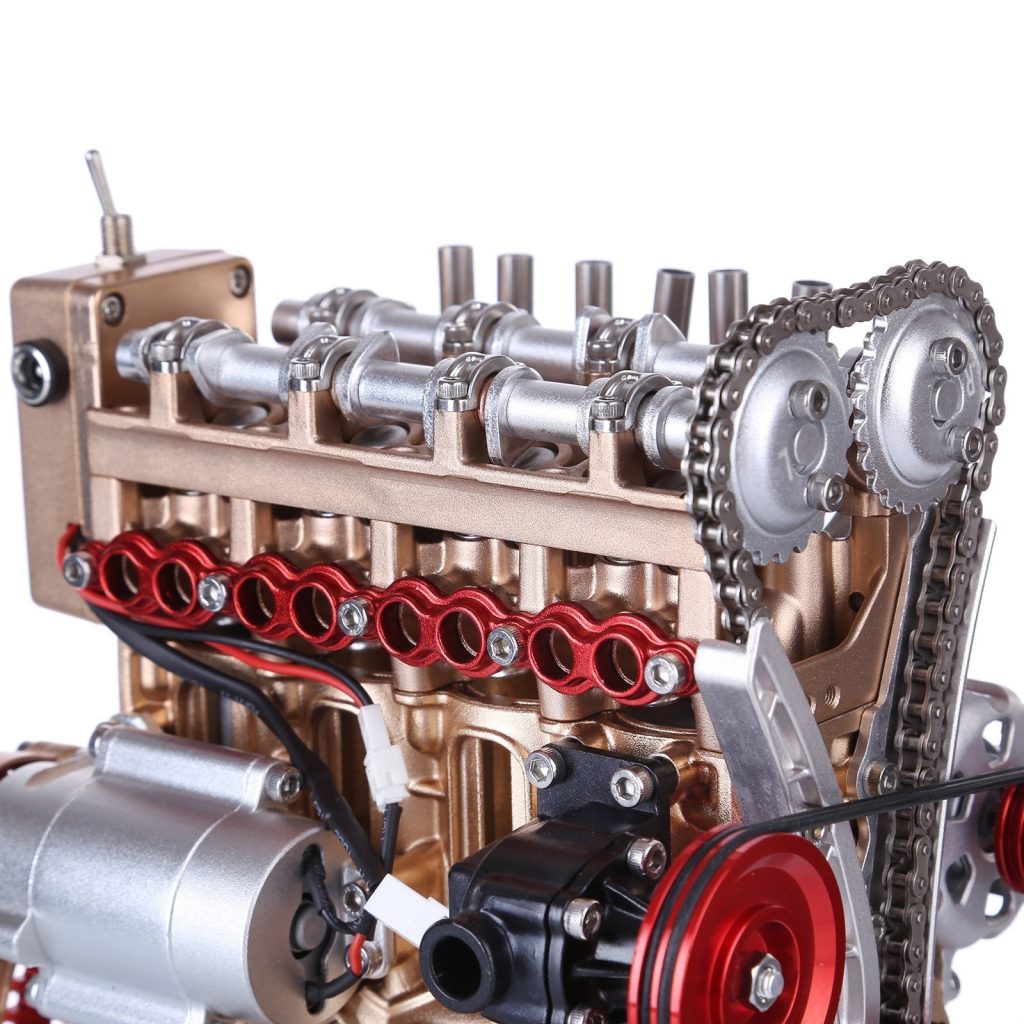

Removal of Old Cylinder

The first phase of the installation process involves the removal of the old or damaged cylinder from the engine block. This necessitates the disassembly of surrounding components such as the cylinder head, piston, and piston rings. Once these components have been removed, the cylinder can be extracted from the engine block using appropriate tools and techniques.

Inspection and Cleaning

After the old cylinder has been removed, the engine block and surrounding components should undergo a thorough inspection and cleaning process. This includes examining the cylinder walls, piston rings, gasket surfaces, and other relevant components for signs of wear, damage, or irregularities. Any dirt, debris, or residue should be meticulously cleaned using appropriate solvents or cleaning agents to ensure a clean and smooth surface for the new cylinder installation.

Preparation of New Cylinder

Prior to installing the new cylinder, it is essential to prepare the component by inspecting its surfaces, ensuring proper lubrication, and verifying its compatibility with the engine block and other components. Additionally, any required gaskets, seals, or related components should be examined and appropriately fitted to ensure a proper seal and prevent potential fluid leaks.

Installation of New Cylinder

The installation of the new cylinder involves carefully fitting the component into the engine block, ensuring proper alignment and securing it in place using appropriate fasteners and torque specifications. It is crucial to verify that the cylinder is seated correctly and aligned with surrounding components to avoid potential issues and to maintain optimal engine performance.

Reassembly of Surrounding Components

Once the new cylinder has been installed, the reassembly of surrounding components such as the piston, piston rings, and cylinder head can commence. This step involves meticulously following manufacturer specifications, torque settings, and other guidelines to ensure proper assembly and alignment of all components.

Post-Installation Procedures

Following the installation of a car engine cylinder, several post-installation procedures and checks are necessary to verify the integrity and functionality of the component and related systems.

Verification and Testing

After completing the installation and reassembly of relevant components, the newly install engine cylinder should undergo thorough verification and testing procedures. This may include performing compression tests, leak-down tests, and other diagnostic procedures to ensure the proper function and integrity of the install cylinder.

Fluid Level Checks

Subsequent to the installation and testing of the new engine cylinder, fluid levels, including engine oil and coolant, should be check and replenish as necessary to maintain proper lubrication and cooling of the engine components.

Quality Assurance and Final Inspection

A final quality assurance and inspection process should be conducte to verify that all installation and post-installation procedures have been complete to specifications. This includes checking for any signs of leaks, irregularities, or malfunctions, and ensuring that all relevant components are secure, align, and functioning as intend.

Advantages of car engine cylinder

Car engine cylinders play a pivotal role in the combustion process. Serving as the key components where fuel and air are compress, ignite. And converte into mechanical energy. The design, efficiency, and functionality of engine cylinders significantly impact a vehicle’s performance. Ffuel economy, and overall power output.

Efficient Power Generation

One of the primary advantages of car engine cylinders is their pivotal role in the generation of power within the internal combustion engine. The controll combustion process that occurs within the cylinders provides the driving force behind the vehicle’s propulsion. Converting chemical energy from the fuel into mechanical energy. As the pistons move in response to the ignition of the air-fuel mixture. The rotating motion translates into the consistent generation of power. Enabling the vehicle to move forward with efficiency and effectiveness.

Optimized Fuel Combustion

Engine cylinders are design to optimize the combustion process. Ensuring efficient and complete ignition of the air-fuel mixture. The precisely engineer design of the cylinders. Along with the placement of the spark plugs and fuel injectors. Facilitates the controll combustion of the fuel. Resulting in high thermal efficiency and reduce waste. The careful choreography of the combustion sequence maximizes the utilization of the fuel. Contributing to improve fuel economy and reduce emissions.

Enhanced Performance

The configuration and number of engine cylinders directly impact a vehicle’s performance. As they determine the engine’s displacement and power output capabilities. Vehicles with larger engine displacements. Which are often achieve through the incorporation of more cylinders. Tend to deliver enhance performance in terms of horsepower, torque, and acceleration. The inherent advantages of engine cylinders, such as balance power delivery and smooth operation. Contribute to the overall performance and driving experience of the vehicle.

Smoothing Operation

The design and arrangement of engine cylinders play a significant role in minimizing vibration. And ensuring smooth operation of the internal combustion engine. The proper balancing of the reciprocating mass and forces within the cylinders helps to reduce mechanical vibrations. Leading to quieter and more refine engine operation. This contributes to overall comfort and driving experience. Particularly in vehicles where a premium on smoothness and quietness is desire.

Conclusion

The installation of a car engine cylinder is a precise and methodical process that requires attention to detail. Adherence to safety precautions, and meticulous execution. By following the step-by-step process outline in this comprehensive guide. Individuals can undertake the installation of a car engine cylinder with confidence and precision. From the preparatory steps and actual installation process to the post-installation procedures. Strict adherence to best practices and manufacturer specifications is essential to ensure the optimal function, reliability. And longevity of the newly install engine cylinder.