Engine Failure Car – The Correct Way to Repair Your Car

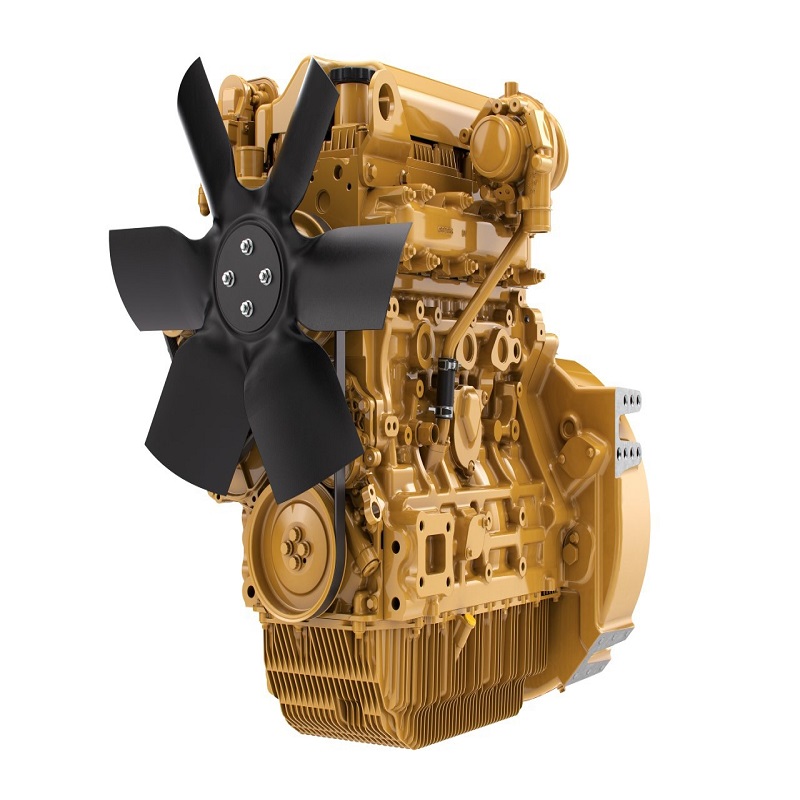

A engine failure car is its heart, powering every journey and ensuring smooth performance. However, like any mechanical system, it is prone to wear and tear, leading to potential failures. Engine failure can be a daunting experience for car owners, often resulting in costly repairs or even the need for a complete replacement. Understanding the causes of engine failure, recognizing the symptoms early, and knowing the appropriate repair methods can help mitigate damage and extend the lifespan of your vehicle. This comprehensive guide will walk you through the common causes of engine failure, how to diagnose problems, and the steps to repair them effectively.

Common Causes of Engine Failure

Before diving into repair techniques, it’s essential to understand what can lead to engine failure car. Identifying the root cause of the problem is the first step toward effective resolution. Here are some of the most prevalent causes:

1. Lack of Maintenance

Regular maintenance is crucial for keeping an engine in good condition. Neglecting oil changes, coolant flushes, and filter replacements can lead to overheating, excessive friction, and eventual breakdowns. For instance, insufficient lubrication can cause metal components to grind against each other, leading to catastrophic engine damage.

2. Overheating

An overheated engine is one of the most common reasons for failure. Overheating can result from a malfunctioning cooling system, low coolant levels, or a clogged radiator. Prolonged exposure to high temperatures can warp cylinder heads, crack engine blocks, and cause gasket failures.

3. Oil Contamination

Contaminated oil—whether due to dirt, water, or fuel—can compromise the engine’s performance. Water intrusion, for example, can occur if there’s a leak in the head gasket, while fuel contamination may happen when the fuel injectors are faulty. Both scenarios reduce the oil’s ability to lubricate properly, increasing wear and tear.

4. Timing Belt/Chain Issues

The timing belt or chain synchronizes the movement of the pistons and valves. If it breaks or slips, the pistons can collide with the valves, causing severe internal damage. This issue is particularly critical because it often requires extensive repairs or a full engine failure car.

5. Poor Fuel Quality

Using low-quality or incorrect fuel can harm your engine over time. Impurities in the fuel can clog injectors, while using the wrong octane rating can lead to knocking (pre-detonation), which damages pistons and cylinders.

Recognizing Symptoms of Engine Failure

Early detection of engine problems can save you from expensive repairs. Keep an eye out for these warning signs that indicate potential engine issues:

1. Unusual Noises

Knocking, ticking, or grinding sounds coming from the engine bay are clear indicators of trouble. These noises could signify worn-out bearings, loose components, or timing issues.

2. Excessive Smoke

Blue smoke typically indicates burning oil, white smoke suggests coolant leakage into the combustion chamber, and black smoke points to unburned fuel. Each type of smoke corresponds to different underlying problems.

3. Decreased Performance

If your car struggles to accelerate, idles roughly, or experiences sudden power loss, it might be suffering from engine problems such as clogged fuel injectors, a failing turbocharger, or compression issues.

4. Check Engine Light

Modern vehicles are equipped with onboard diagnostics (OBD) systems that monitor engine health. When the check engine light illuminates, use an OBD scanner to retrieve error codes and pinpoint the issue.

5. Fluid Leaks

Oil, coolant, or transmission fluid leaks are telltale signs of engine trouble. Regularly inspect your driveway or parking spot for puddles and address any leaks promptly.

Step-by-Step Guide to Repairing Engine Failures

Once you’ve identified the problem, it’s time to take action. Below is a detailed breakdown of various repair methods depending on the nature of the engine failure.

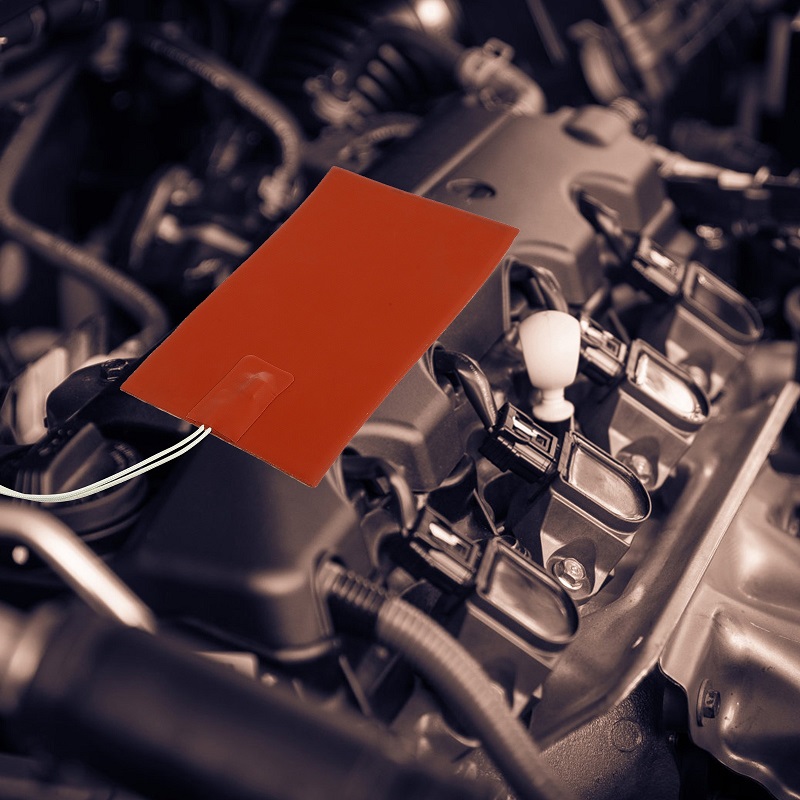

1. Addressing Oil-Related Problems

- Change the Oil: If the engine has been running on old or contaminated oil, drain the existing oil completely and replace it with fresh, high-quality oil recommended by the manufacturer.

- Inspect Gaskets and Seals: Look for leaks around gaskets and seals, especially the head gasket. Replace damaged parts to prevent further contamination.

- Flush the System: In cases of severe contamination, consider flushing the entire lubrication system to remove debris and sludge.

2. Repairing Cooling System Issues

- Check Coolant Levels: Ensure the coolant reservoir is filled to the appropriate level. Refill with the correct type of coolant if necessary.

- Inspect the Radiator: Clean or replace a clogged radiator to improve heat dissipation. Also, check for leaks and repair them immediately.

Causes of engine failure car

The engine is undoubtedly the most critical component of any vehicle, serving as its powerhouse. It converts fuel into mechanical energy, propelling the car forward and ensuring smooth operation. However, engines are not immune to failure, and when they do fail, it can lead to costly repairs or even render the vehicle unusable. Engine failure can stem from a variety of causes, ranging from poor maintenance habits to manufacturing defects. Understanding these causes is crucial for preventing breakdowns and extending the life of your vehicle. In this article, we will delve into the primary reasons why car engines fail, providing insights that can help you avoid such issues in the future.

Lack of Regular Maintenance

One of the most common and preventable causes of engine failure is neglecting routine maintenance. Modern engines are designed to operate efficiently under specific conditions, but they require regular upkeep to function optimally.

Infrequent Oil Changes

Oil serves as the lifeblood of an engine, lubricating moving parts and reducing friction. Over time, oil breaks down and becomes contaminated with dirt, debris, and metal particles. If not replaced regularly, old oil loses its effectiveness, leading to increased wear and tear on engine components. This can result in scoring of cylinder walls, worn-out bearings, and eventual engine seizure.

Ignoring Air Filter Replacements

The air filter ensures that clean air enters the engine for combustion. A clogged or dirty air filter restricts airflow, causing the engine to work harder and consume more fuel. Prolonged neglect can lead to reduced performance, overheating, and even damage to internal components.

Neglecting Coolant System Maintenance

Coolant plays a vital role in regulating engine temperature. Failing to flush and replace coolant at recommended intervals can lead to corrosion, blockages, and overheating. These issues can cause severe damage, including warped cylinder heads and cracked engine blocks.

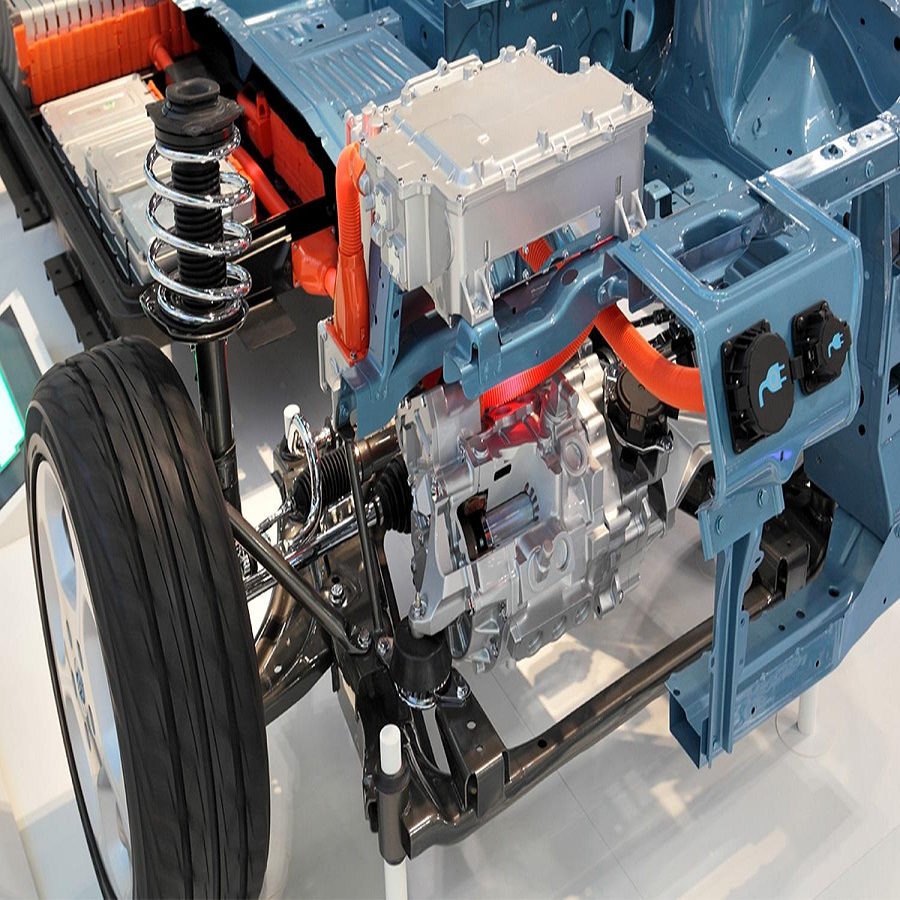

Overheating: A Silent Killer

Overheating is one of the most frequent culprits behind engine failure. When an engine runs too hot, vital components expand beyond their tolerances, leading to catastrophic damage.

Cooling System Failures

The cooling system, which includes the radiator, water pump, thermostat, and hoses, is responsible for dissipating heat generated by the engine. A malfunctioning water pump, leaking radiator, or stuck thermostat can disrupt this process, causing the engine to overheat.

Low Coolant Levels

Low coolant levels are often caused by leaks in the system. Even small leaks can escalate quickly, leaving the engine without adequate cooling. Driving with insufficient coolant can result in thermal stress, cracking the engine block or warping critical components.

External Factors Contributing to Overheating

External factors such as towing heavy loads, driving in extreme weather conditions, or operating the vehicle in stop-and-go traffic can exacerbate overheating. Without proper precautions, these situations can push the engine beyond its limits.

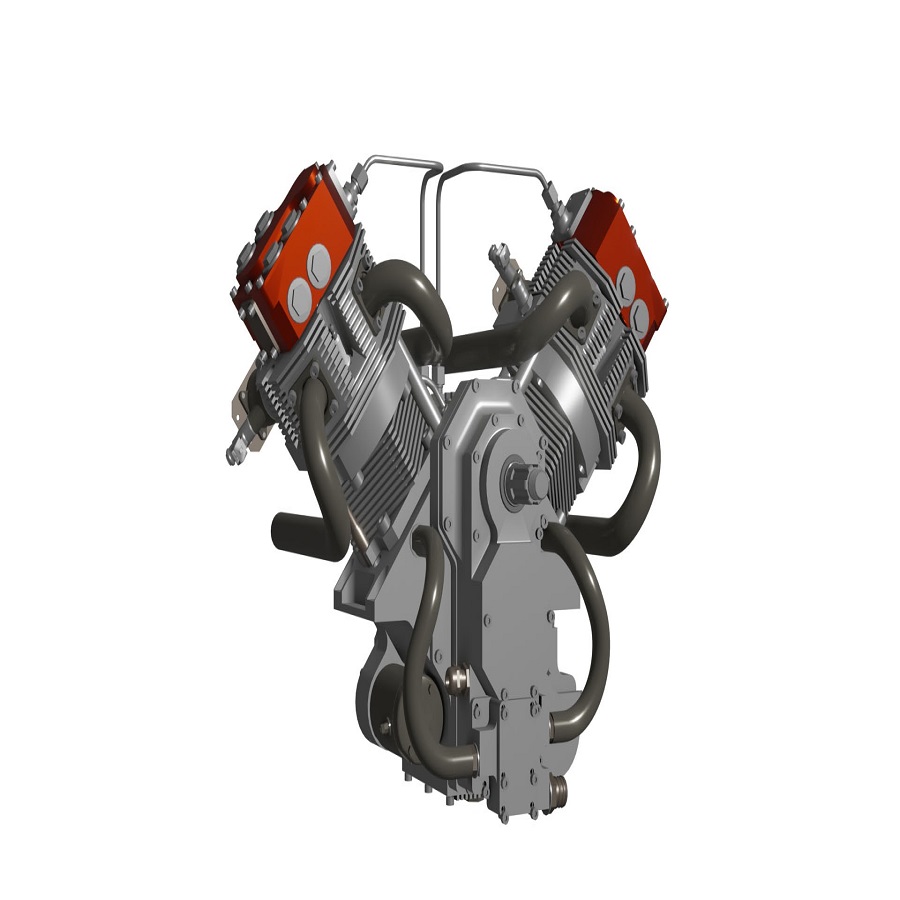

Timing Belt/Chain Issues

The timing belt or chain is a crucial component that synchronizes the movement of the engine’s pistons and valves. A failure in this area can lead to devastating consequences.

Timing Belt Breakage

Timing belts are made of rubber and have a limited lifespan, typically between 60,000 and 100,000 miles. If the belt breaks while the engine is running, the pistons may collide with the valves, causing bent valves, damaged pistons, and extensive internal damage. This type of failure often requires a complete engine rebuild or replacement.

Stretched or Worn Timing Chains

Unlike timing belts, timing chains are designed to last the lifetime of the vehicle. However, they can stretch or become loose over time, especially in older models. A stretched timing chain can throw off the synchronization of the engine, leading to misfires, loss of power, and eventual failure.

Incorrect Installation

Improper installation of a new timing belt or chain can also lead to engine failure. Misalignment during installation can cause the same kind of damage as a broken belt, highlighting the importance of professional servicing.