How Many Engine Mounts Does a Car Have?

How many engine mounts does a car have? Engine mounts are an essential component of a car’s suspension system that provides support and stability to the engine. They are designed to absorb and minimize the vibrations and movements produced by the engine, ensuring a smooth and comfortable ride for the passengers. In this article, we will explore the importance of engine mounts in a car and discuss their functions, types, and maintenance.

Functions of Engine Mounts

The main function of engine mounts is to secure the engine to the car’s chassis and minimize the transmission of vibrations, noise, and harshness (NVH) to the cabin. They also help to maintain proper alignment and positioning of the engine, ensuring optimal performance and reducing wear and tear on other components. Additionally, engine mounts aid in absorbing and dampening the shocks and impacts generated by the road surface, thus improving the overall stability and handling of the vehicle.

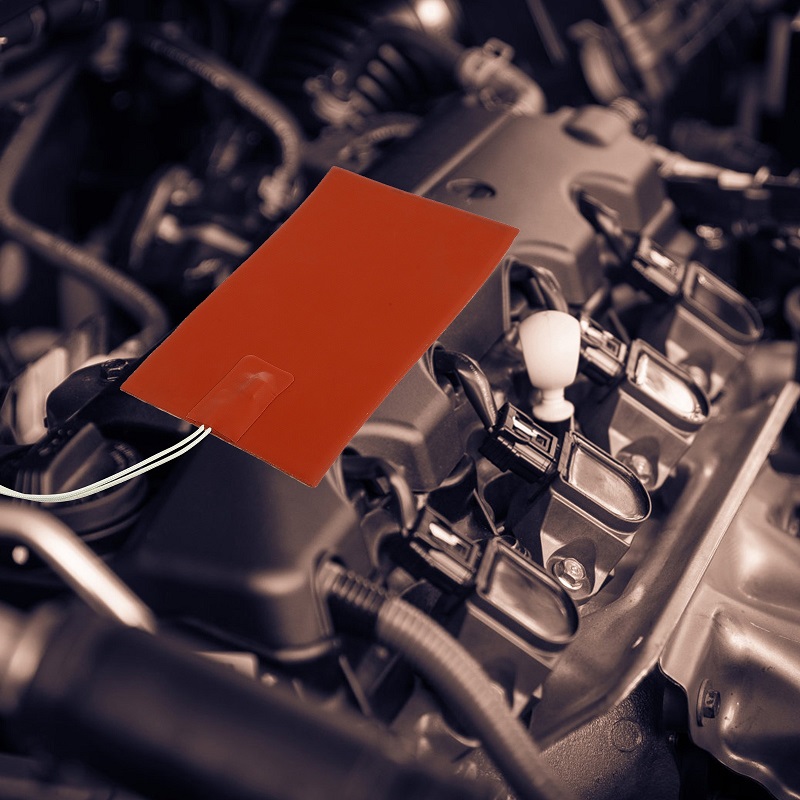

Types of Engine Mounts

There are several types of engine mounts used in modern cars, including conventional rubber mounts, hydraulic mounts, and active mounts. Conventional rubber mounts are the most common type and are made of rubber or a similar elastomeric material, which provides a good balance of stiffness and flexibility. Hydraulic mounts, on the other hand, use a fluid-filled chamber to dampen vibrations and provide smoother operation. Active mounts utilize electronic sensors and actuators to actively adjust the stiffness of the mount based on driving conditions, further enhancing ride comfort and performance.

Number of Engine Mounts in a Car

A typical car has multiple engine mounts, with the exact number depending on the engine configuration and size. Most cars have three to four engine mounts, with some larger vehicles or high-performance models having additional mounts to support the heavier and more powerful engines. The front and rear mounts are usually located near the engine’s transmission, while the side mounts are positioned on the sides of the engine, providing comprehensive support and stability.

Maintenance of Engine Mounts

Like any other component in a car, engine mounts require proper maintenance to ensure their long-term functionality and performance. Regular inspection of the mounts for signs of wear, damage, or deterioration is crucial, and any worn or damaged mounts should be replaced promptly to prevent further damage to the engine and other parts of the vehicle. It is also important to inspect and replace the mounts’ associated hardware, such as bolts and brackets, to ensure a secure and stable connection between the engine and chassis.

How to repair engine mounts

Engine mounts play a crucial role in the proper functioning of a vehicle’s engine. They are responsible for holding the engine in place and reducing the transmission of vibration and noise to the vehicle’s cabin. Over time, engine mounts can wear out and fail, leading to a variety of issues such as excessive engine movement, increased noise and vibration, and even damage to other components.

Inspection

The first step in maintaining engine mounts is to inspect them for any signs of wear or damage. This can be done visually by looking for cracks, tears, or signs of leaking fluid. Additionally, the engine mounts should be checked for excessive movement by applying pressure to the engine and observing any movement or play in the mounts.

Replacing Engine Mounts

If any signs of wear or damage are detect during the inspection, it is necessary to replace the engine mounts. This process involves several steps and should be done carefully to ensure proper installation.

- Lift the Vehicle: The first step in replacing engine mounts is to safely lift the vehicle using a hydraulic jack and place it on jack stands for support.

- Locate the Engine Mounts: Once the vehicle is lift. Locate the engine mounts that need to be replace. They are typically locat on either side of the engine, as well as at the front and rear.

- Remove the Old Mounts: Using a combination of ratchets, sockets, and wrenches. Remove the bolts that secure the engine mounts to the engine and chassis. Carefully disconnect any electrical connections or hoses that may be attach to the mounts.

- Install the New Mounts: With the old mounts remove. Carefully install the new mounts in their place. Make sure to align the mounts properly. And tighten the bolts securely to prevent any movement.

- Lower the Vehicle: Once the new mounts are install. Carefully lower the vehicle back to the ground and remove the jack stands.

- Test the Engine: Start the engine and allow it to run for a few minutes to ensure that the new mounts are holding the engine in place and reducing vibration and noise.

Preventative Maintenance

In addition to regular inspections and replacements. There are several preventative maintenance measures that can be taken to extend the life of engine mounts.

Avoid Rough Driving:

Rough driving such as excessive speeding, hard braking. And erratic acceleration can put extra strain on engine mounts and cause them to wear out prematurely. Therefore, it is important to drive carefully and avoid unnecessary roughness on the road.

Regularly Check Fluid Levels:

Engine mounts are often fill with hydraulic fluid to help absorb vibrations and keep the engine stable. Regularly checking the fluid levels and topping them up as need can help prevent premature failure of the mounts.

Perform Engine Maintenance:

Regular maintenance of the engine, such as oil changes and tune-ups. Can help reduce the amount of vibration and strain place on the mounts, ultimately extending their lifespan.

What are engine mounts?

Engine mounts are one of the most critical components of a vehicle’s engine system. They play a crucial role in supporting the engine and ensuring smooth operation while the vehicle is in motion.

Function of Engine Mounts

Vibration Dampening:

One of the most important functions of engine mounts is to dampen the vibrations produce by the engine. As the engine operates, it generates intense vibrations and movements. Without engine mounts, these vibrations would be transmit to the vehicle’s frame. Resulting in a rough and uncomfortable ride for the occupants. Engine mounts absorb these vibrations. Preventing them from being transfer to the rest of the vehicle.

Noise Reduction:

In addition to dampening vibrations. Engine mounts also help reduce the noise produced by the engine. By isolating the engine from the chassis, they prevent the transmission of engine noise. Resulting in a quieter and more pleasant driving experience for the occupants.

Engine Stability:

Engine mounts also play a crucial role in maintaining the stability and alignment of the engine. They help to secure the engine in place. Preventing it from shifting or moving during acceleration, deceleration, and turns. This ensures that the engine remains properly align with the transmission and other drivetrain components. Optimizing the overall performance and efficiency of the vehicle.

Impact on Vehicle Performance

The quality and condition of engine mounts can have a significant impact on the overall performance of the vehicle. Worn or damage engine mounts can lead to a range of issues, including excessive engine movement. Increase noise and vibrations, and compromise stability. These issues can negatively affect the vehicle’s handling, ride comfort, and fuel efficiency. Making it crucial to regularly inspect and maintain engine mounts.

Conclusion

Engine mounts play a critical role in maintaining the stability, comfort, and performance of a car. By absorbing and reducing engine vibrations. They contribute to a smoother ride and improve handling while also protecting the engine and surrounding components from excessive wear and damage. Understanding the functions, types. And maintenance of engine mounts is essential for every car owner. As it can help prolong the life of the vehicle and ensure a safe and enjoyable driving experience.