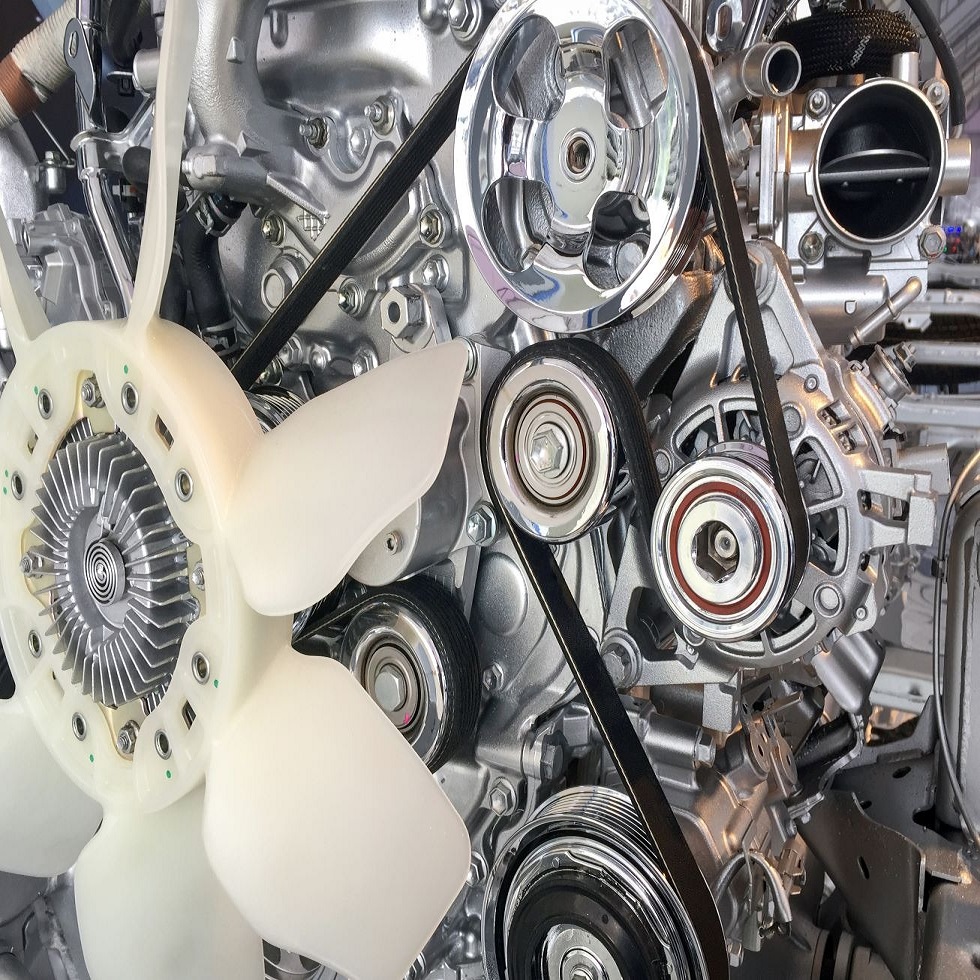

Belt For Car Engine – A Very Important Car Part

A belt for car engine is a crucial component of the vehicle’s system, as it helps to drive various engine accessories such as the alternator, power steering pump, and air conditioning compressor. If the belt becomes worn or damaged, it can lead to serious problems with the engine’s performance. In this article, we will discuss the step-by-step process of installing a belt for a car engine, ensuring that it is done correctly and safely.

Preparing for Installation

Before beginning the installation process, it is important to gather the necessary tools and materials. You will need a new belt that is the correct size and type for your specific car model, as well as a belt tension gauge, socket set, and a service manual for your vehicle. It is also recommended to wear safety goggles and gloves throughout the installation process to protect yourself from any potential hazards.

Step 1: Locate and Access the Belt

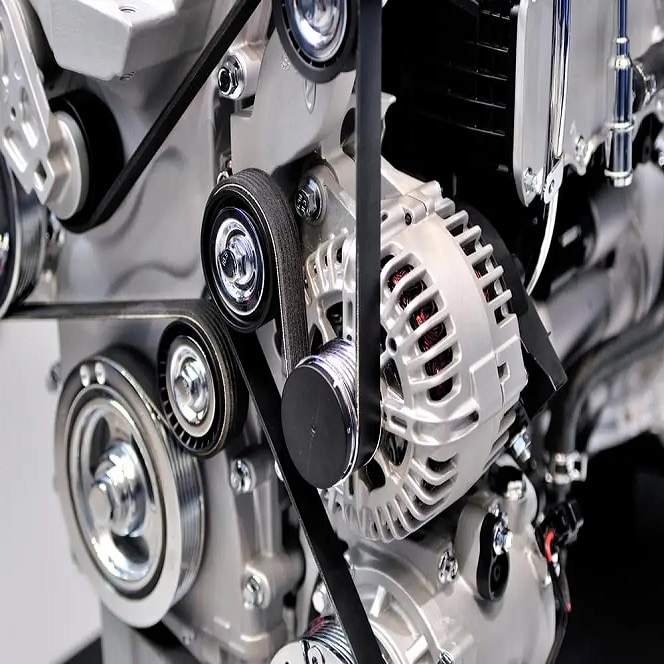

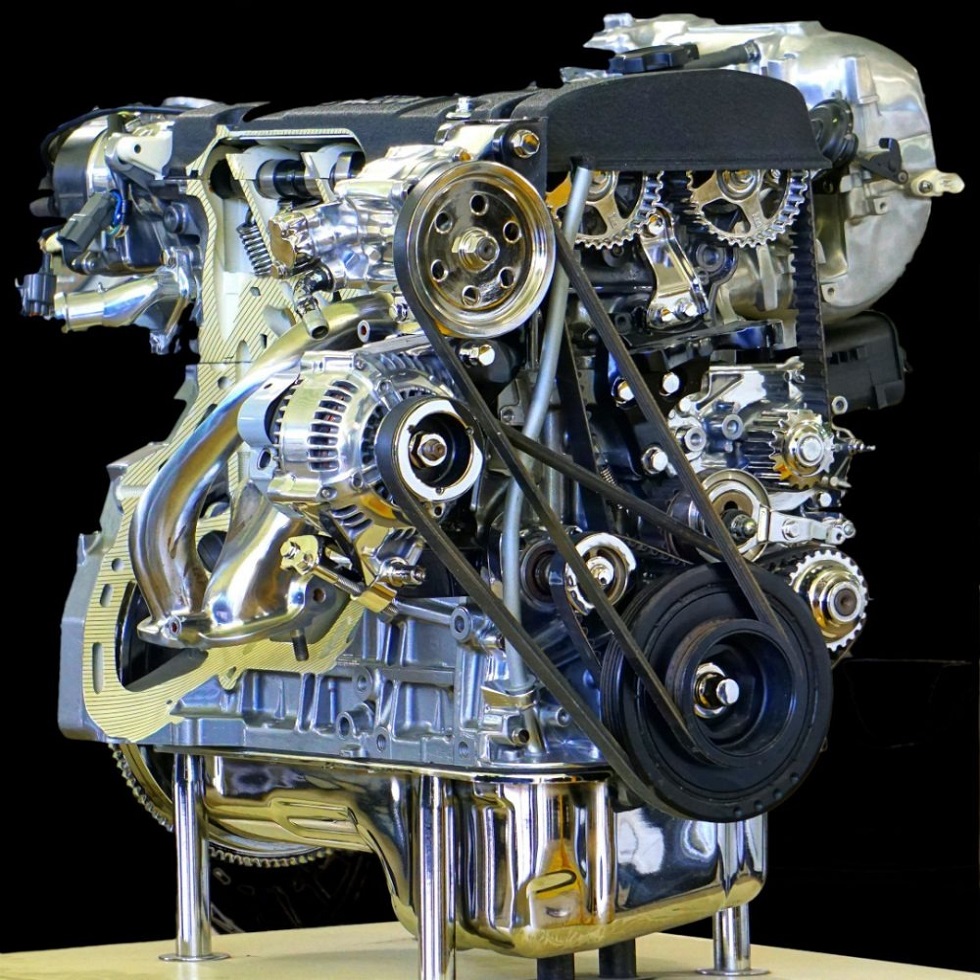

The first step in installing a belt for a car engine is to locate the existing belt and access it for removal. Depending on the make and model of your vehicle, the belt may be located on the front, side, or back of the engine. Refer to your service manual to find the exact location of the belt and familiarize yourself with the belt routing diagram to ensure correct installation.

Step 2: Remove the Old Belt

Using the appropriate socket set, carefully loosen the tension on the old belt by turning the tensioner pulley bolt. Once the tension has been released, slide the old belt off of the pulleys and remove it from the engine. Take note of the belt routing as you will need to follow the same pattern when installing the new belt.

Step 3: Inspect the Pulleys

Before installing the new belt, take a moment to inspect the pulleys to ensure that they are in good condition. Look for any signs of damage or wear, such as cracks, chips, or grooves, and replace any pulleys that show signs of significant damage. It is also a good idea to clean the pulleys with a cloth to remove any built-up debris or grime.

Install the New Belt

Carefully route the new belt around the pulleys, following the same pattern as the old belt. Refer to the belt routing diagram in your service manual to ensure correct placement. Once the belt is in position, use the belt tension gauge to measure the tension of the belt. Adjust the tensioner pulley as needed to achieve the correct tension, as specified in the service manual for your vehicle.

Double-Check the Installation

After the new belt has been installed and tensioned, double-check the positioning to ensure that it is properly seated on all of the pulleys. Spin the engine by hand to check for any obstructions or misalignments. Additionally, inspect the belt for any twists or kinks, as these can cause premature wear and damage to the belt.

Test the Engine

Once you are confident that the new belt has been installed correctly, start the engine to test its performance. Listen for any unusual noises or vibrations that may indicate a problem with the belt installation. If everything sounds and feels normal, you can be confident that the new belt is functioning properly.

How to repair belt for car engine failure

One of the most common issues with car engines is a malfunctioning belt. A failing engine belt can cause various problems, including overheating, loss of power steering, and battery drainage.

Diagnosing the issue

The first step in fixing a malfunctioning engine belt is to diagnose the issue. Signs of a failing belt include loud squealing noises, engine overheating, loss of power steering, and battery draining. If you experience any of these symptoms, it is essential to stop driving the car immediately and locate the source of the problem.

Inspecting the belt

After identifying the symptoms of a failing belt, the next step is to inspect the belt itself. Open the hood of the car and locate the engine belt. Check for any signs of wear and tear, such as cracks, fraying, or glazing. Additionally, ensure that the belt is properly tensioned and aligned with the pulleys. If you notice any visible damage to the belt, it is likely the cause of the issue.

Replacing the belt

Once you have identified the problem with the belt, the next step is to replace it. In most cases, replacing an engine belt is a relatively straightforward task. Start by loosening the tension on the old belt and remove it from the pulleys. Take note of the belt routing to ensure proper installation of the new belt. Install the new belt and adjust the tension to the manufacturer’s specifications. Finally, start the car and check for any abnormal noises or vibration.

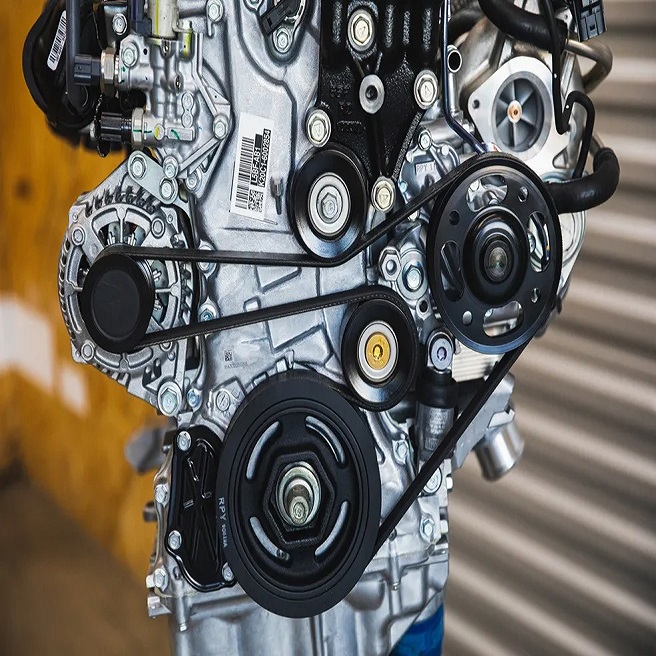

Checking the pulleys and tensioner

In some cases, a failing belt may be caused by damaged pulleys or a faulty tensioner. After replacing the belt, it is essential to inspect the pulleys and tensioner for any signs of damage or wear. If you notice any issues, it is advisable to replace the damaged components to prevent future belt failures.

Testing the repair

After replacing the belt and inspecting the pulleys and tensioner, it is crucial to test the repair. Start the car and listen for any abnormal noises coming from the engine. Additionally, check the power steering and ensure that the engine is not overheating. If everything is functioning properly, the repair was successful.

Advantages of belt for car engine

The belt for car engine plays a significant role in ensuring the smooth and efficient operation of the vehicle. It is a crucial component that connects the engine to other important parts of the car, such as the alternator, air conditioning compressor, power steering pump, and water pump.

Improves Power Transmission

One of the key benefits of using a belt for car engine is its ability to improve power transmission. The belt connects the engine to various accessories, such as the alternator and air conditioning compressor, allowing them to operate efficiently. This ensures that the car’s electrical system functions properly and the cabin is cooled effectively. Additionally, the belt also drives the water pump, which helps to regulate the temperature of the engine, preventing it from overheating. By efficiently transmitting power to these components, the belt contributes to the overall performance and functionality of the vehicle.

Reduces Maintenance Costs

Another advantage of using a belt for car engine is that it helps to reduce maintenance costs. Belts are made from durable materials, such as rubber and synthetic compounds, which are designed to withstand high temperatures and constant use. This means that they require minimal maintenance and are less likely to break or wear out prematurely. As a result, car owners can save on maintenance costs and avoid the inconvenience of unexpected breakdowns or repairs.

Conclusion

Installing a belt for a car engine is a relatively straightforward process, but it is important to take the time to do it correctly to avoid potential issues with the engine’s performance. By following the steps outlined in this article and referring to your service manual for specific guidance, you can ensure that the new belt is installed safely and effectively. Remember to perform regular maintenance on the belt to keep it in good condition and prevent premature wear and damage.