Turbine Car Engine – Important Car Parts

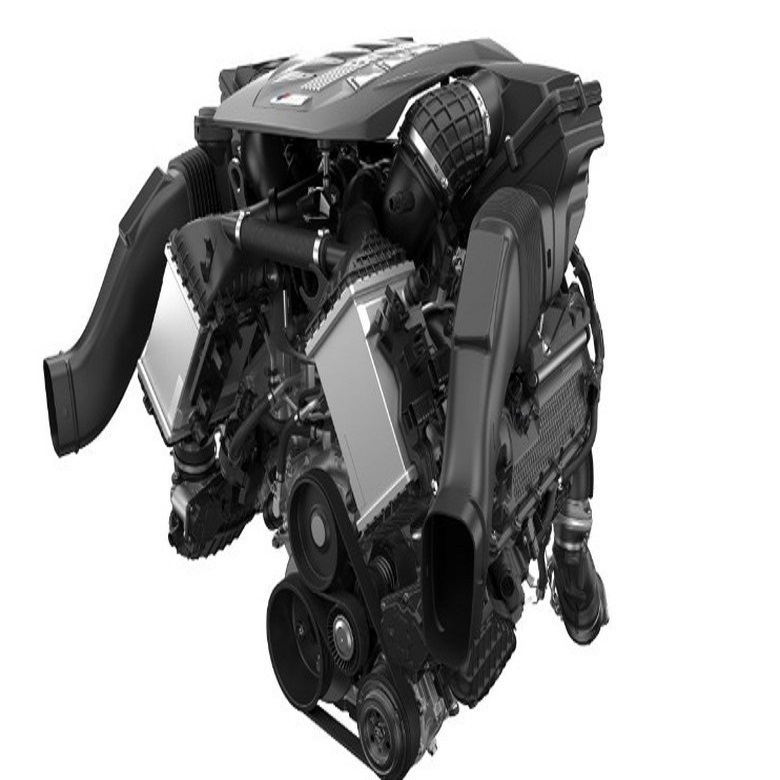

The installation of a turbine car engine can be a complex process, but with the right knowledge and preparation, it can be done successfully. Turbine car engines offer several advantages, including high power output and reliability. In this guide, we will provide step-by-step instructions on how to install a turbine car engine to ensure optimal performance and efficiency.

Pre-Installation Planning

Before starting the installation process, it is important to carefully plan and prepare for the task ahead. Here are some key pre-installation steps to take:

- Gather all necessary tools and equipment: Ensure that you have all the tools and equipment required for the installation, including wrenches, sockets, ratchets, hoists, and engine lifting brackets.

- Review the engine manual: Familiarize yourself with the turbine car engine’s manual to understand its specifications, installation requirements, and any specific guidelines.

- Inspect the engine mounts: Check the condition of the engine mounts and replace them if necessary to ensure proper support for the new engine.

- Prepare the engine bay: Clean and prepare the engine bay by removing any obstructions, old components, and debris to create a clear working space.

Engine Installation Steps

Once you have completed the pre-installation planning, you can proceed with the following steps to install the turbine car engine:

- Position the engine: Use an engine hoist to carefully position the turbine car engine over the engine bay, ensuring that it is aligned with the engine mounts and transmission.

- Secure the engine: Once the engine is in place, secure it using high-quality bolts and brackets to prevent any movement or shifting during operation.

- Connect the wiring harness: Carefully connect the wiring harness to the appropriate engine sensors, ignition system, and other electrical components.

- Install the exhaust system: Position and install the exhaust system to ensure proper ventilation and emission control for the turbine car engine.

- Check fluid levels: Fill the engine with the necessary fluids, including oil, coolant, and fuel, and inspect for any leaks or abnormalities.

- Test the engine: Start the engine and perform a thorough test to ensure that it is running smoothly and without any issues.

Post-Installation Inspection

After the turbine car engine is installed, it is important to conduct a post-installation inspection to ensure that everything is functioning as intended. Here are some key post-installation inspection steps to take:

- Check for leaks: Inspect the engine and surrounding components for any signs of leaks or fluid seepage and address any issues accordingly.

- Perform a test drive: Take the vehicle for a test drive to evaluate the performance of the turbine car engine under real-world conditions.

- Monitor engine vitals: Use diagnostic tools to monitor the engine’s vitals, including temperature, pressure, and exhaust emissions, to ensure that it is operating within safe parameters.

Maintenance precautions for turbine car engine

Turbine car engines have gained popularity due to their efficiency and high power output. However, like any other car engine, they also require regular maintenance to ensure optimal performance and longevity.

Regular Inspection

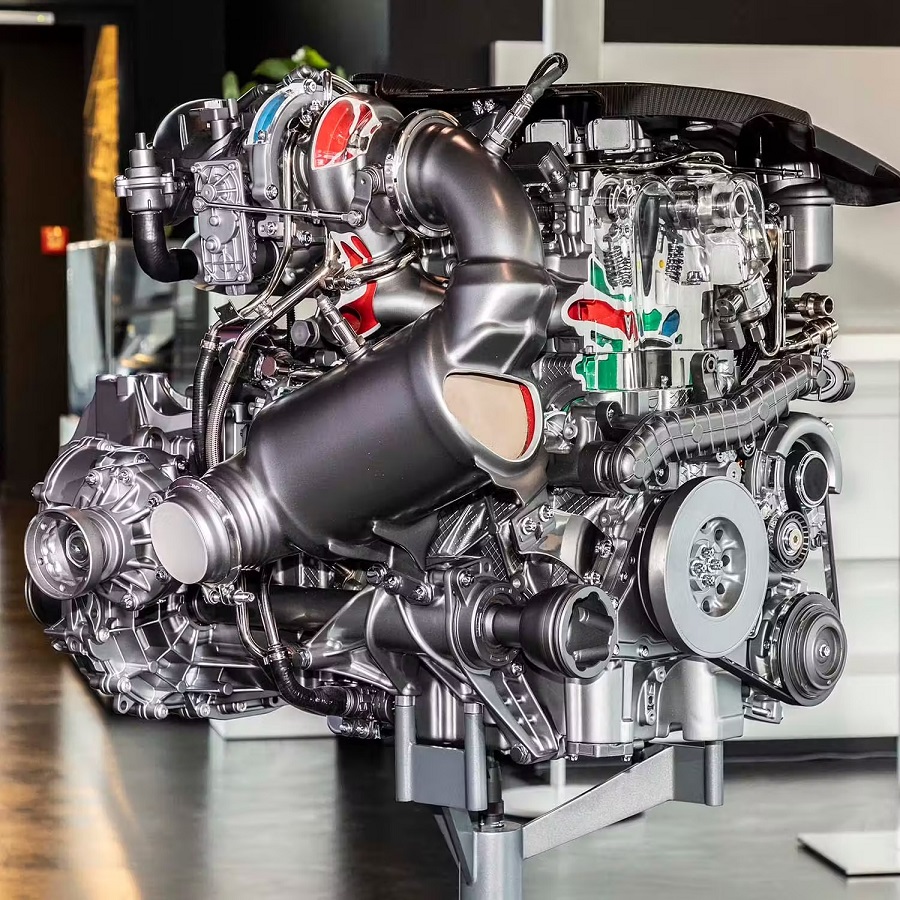

One of the key maintenance tips for turbine car engines is to conduct regular inspections. This includes checking for any signs of wear and tear, leaks, and loose fittings. It is important to inspect the turbine blades, combustion chamber, and exhaust system for any damages or malfunctions. By conducting regular inspections, you can identify and address any potential issues before they escalate into major problems.

Oil and Filter Changes

Another important aspect of maintenance for turbine car engines is to perform regular oil and filter changes. The oil lubricates the moving parts of the engine and helps to reduce friction and wear. Over time, the oil can become contaminated with dirt and debris, leading to reduced engine performance. Therefore, it is crucial to change the oil and filter according to the manufacturer’s recommendations.

Cooling System Maintenance

The cooling system of a turbine car engine is essential for regulating the temperature and preventing overheating. It is important to check the coolant levels, hoses, and radiator for any leaks or damages. Additionally, the cooling system should be flushed and refilled with fresh coolant at regular intervals to ensure efficient heat dissipation.

Fuel System Maintenance

The fuel system of a turbine car engine plays a crucial role in delivering the right amount of fuel to the combustion chamber. To maintain optimal performance, it is important to inspect the fuel lines, filters, and injectors for any clogs or leaks. Regular fuel system maintenance can help ensure proper fuel delivery and combustion, leading to improved engine performance.

Air Intake and Exhaust System

The air intake and exhaust system of a turbine car engine are responsible for providing the engine with a steady flow of air and expelling exhaust gases. It is important to inspect the air filters, intake pipes, and exhaust components for any obstructions or damages. Keeping these components clean and free from debris can help maintain an optimal air/fuel ratio and reduce harmful emissions.

Electronic Systems and Sensors

Modern turbine car engines are equipped with advanced electronic systems and sensors that play a crucial role in engine performance and emissions control. It is important to inspect and test the electronic control unit (ECU), sensors, and wiring for any faults or malfunctions. Regular testing and diagnosis of electronic systems can help identify and address potential issues before they affect engine performance.

Professional Maintenance

While some maintenance tasks for turbine car engines can be performed by car owners, it is also important to seek professional maintenance services at regular intervals. Professional technicians have the expertise and tools to conduct thorough inspections and address any complex issues that may arise. Additionally, professional maintenance can help ensure that the engine is in compliance with manufacturer specifications and standards.

How to choose a turbine car engine

When it comes to selecting a car engine, there are many options available in the market. One such option is the turbine car engine, which has gained popularity due to its unique design and performance capabilities.

Power Output

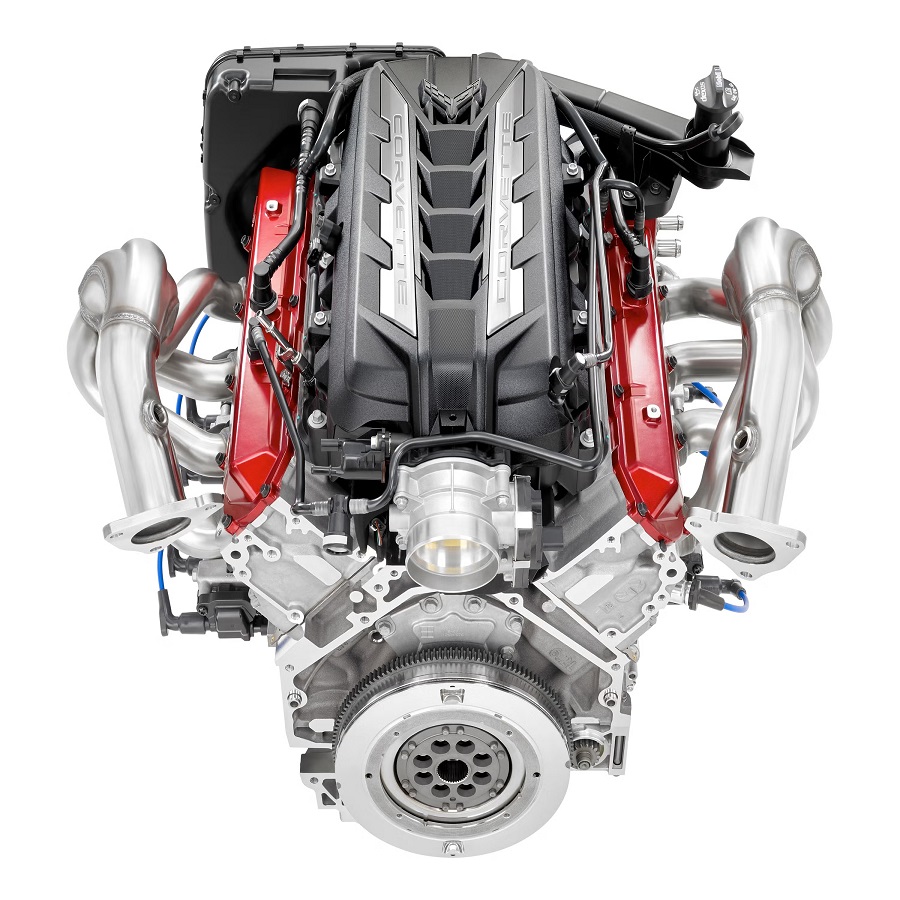

One of the most important factors to consider when choosing a turbine car engine is its power output. The power output of an engine is measure in horsepower (HP) or kilowatts (kW) and determines the performance capabilities of the vehicle. When evaluating the power output of a turbine car engine, it is important to consider factors such as the intend use of the vehicle, the terrain it will be driven on, and the weight of the vehicle. For instance, if you are looking to install a turbine car engine in a high-performance sports car, you may prioritize engines with higher power output. On the other hand, if you are looking for a more fuel-efficient option for everyday driving, a lower power output engine may be more suitable.

Fuel Efficiency

Another important factor to consider when selecting a turbine car engine is its fuel efficiency. Fuel efficiency refers to the engine’s ability to convert fuel into energy. And is typically measure in miles per gallon (MPG) or liters per 100 kilometers (L/100km). A more fuel-efficient engine will result in lower fuel consumption and reduce operating costs. When evaluating the fuel efficiency of a turbine car engine. It is important to consider factors such as the type of fuel it uses, its combustion process. And any additional technologies or features that contribute to better fuel economy.

Conclusion

Installing a turbine car engine requires careful planning. Attention to detail, and precision. By following the steps outline in this guide. You can successfully install a turbine car engine and enjoy its benefits for years to come. Remember to consult the engine manual. And seek professional assistance if need to ensure a smooth and efficient installation process.